Powder Coating Powder Secrets: Achieve a Smoother, Longer-Lasting Finish

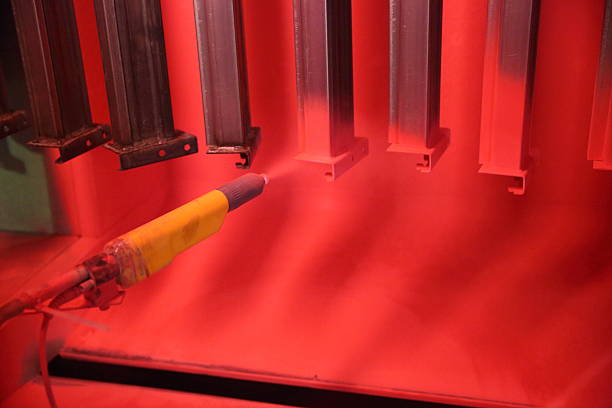

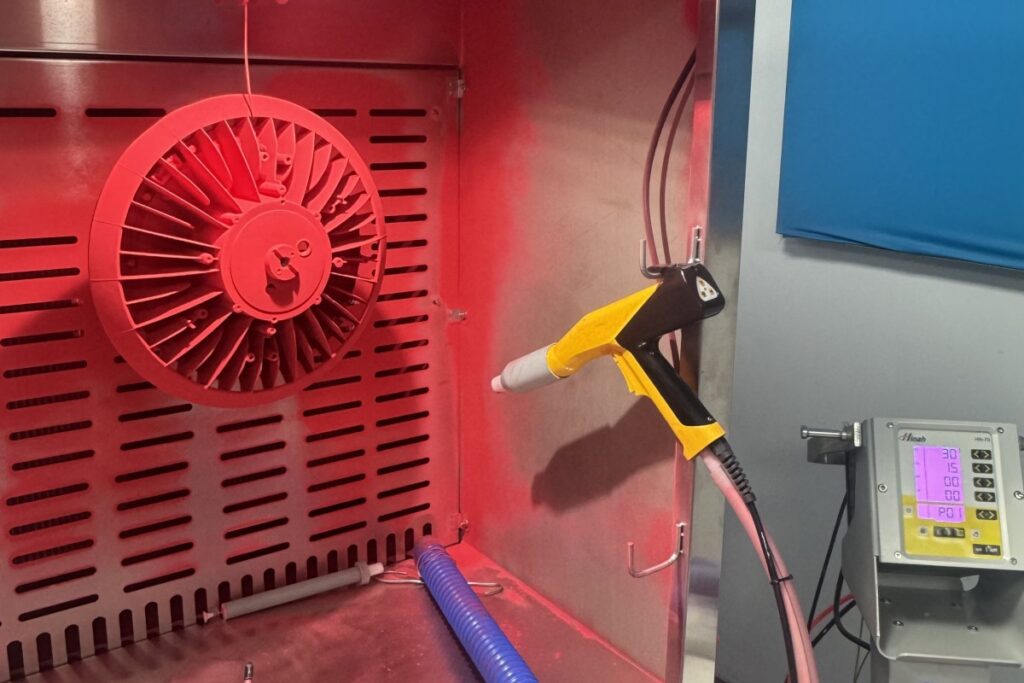

You’ve dialed in your spray settings, maintained your equipment meticulously, and followed the curing schedule – yet that perfectly smooth, durable powder coating finish still feels elusive. Fading, chipping, or an inconsistent texture can plague even experienced coaters, leading to frustrating rework, wasted materials, and unhappy customers. Often, the culprit isn’t the process or the gun; it’s the powder itself.

While equipment gets the spotlight, the powder coating powder is the critical, unsung hero determining ultimate quality and longevity. Its hidden properties – chemistry, particle science, and handling needs – hold the secrets to unlocking a flawlessly smooth application and a finish that lasts years, not months. This article exposes those essential powder secrets, empowering you to achieve superior results and significant savings. Stop battling imperfections; start mastering the core ingredient.

Secret #1: Chemistry is King – It’s More Than Just Color

Choosing a powder coating isn’t just about color swatches. The resin system is the foundation of your finish’s performance – dictating durability, environmental resistance, and longevity. Epoxy resins excel in chemical resistance and adhesion but degrade rapidly under UV light, making them ideal for indoor machinery or lab equipment. Polyesters offer superior UV stability and flexibility, perfect for automotive wheels or outdoor furniture, though they sacrifice some chemical resistance. Hybrids strike a balance: cost-effective for appliances or general fixtures but lack extreme performance. Ignoring resin compatibility with your project’s environment guarantees failure – imagine epoxy on a sun-exposed garden bench chalking within months, or polyester blistering on chemical tanks.

Up to 15% of a powder’s composition comprises specialized additives that elevate performance:

- Flow agents ensure smooth leveling, eliminating orange peel;

- Degassers release trapped air to prevent craters and pinholes;

- UV stabilizers act as a “sunscreen” against fading and chalking;

- Texture modifiers create matte, metallic, or wrinkled finishes.

Particle Behavior | Ideal Size/Distribution | Consequences of Poor Control |

Fluidization | 30-50μm, narrow spread | Clogged lines, pulsating spray |

Transfer Efficiency | 35-45μm | 20-40% overspray waste |

Faraday Cage Penetration | <40μm | Uncoated corners, manual touch-up |

Film Smoothness | Tight distribution (±5μm) | Orange peel, texture variation |

Secret #2: Particle Size & Distribution – The Hidden Key to Flow & Coverage

Your powder’s chemistry could be flawless, but if its particles resemble irregular gravel, achieving a smooth, efficient finish is impossible. Particle size (measured in microns) and distribution are the invisible architects of your coating’s success, dictating everything from gun performance to final appearance. Optimal particles between 30-50 microns fluidize like heavy cream, flowing smoothly through equipment without clogs, while fines (<25μm) create dusty overspray that wastes 15-30% of material and oversized chunks (>65μm) cause craters and orange peel by resisting melting. For deep recesses (Faraday cages), particles under 40 microns are essential to penetrate edges uniformly. Crucially, narrow distribution (tight ±5μm variance) ensures consistent charging, deposition, and melt-flow for glass-smooth results, whereas broad spreads mix ultrafine dust and coarse granules – sabotaging transfer efficiency and creating texture defects. The secret? Demand a particle size distribution graph (not just average size) to verify rigorous air classification; premium powders remove fines/oversize, turning physics from foe to ally.

Secret #3: Curing Profile – Precision Beyond the Oven Temp

Dialing in your oven temperature is only half the battle – true curing precision lies in mastering the time-temperature relationship, where even minor deviations sabotage adhesion, durability, and chemical resistance. Powder coatings rely on exact thermal exposure to trigger cross-linking: the molecular bonding that transforms loose powder into a unified, resilient film. Under-cure (insufficient time/temp) leaves bonds incomplete, causing poor adhesion, brittleness, and premature peeling – imagine a factory-fresh bicycle frame chipping after its first trail ride. Over-cure (excessive heat/time) degrades resins, leading to discoloration, lost flexibility, and compromised UV resistance, like automotive wheels yellowing under summer sun. Critically, each powder formulation has a unique cure schedule (e.g., 10 mins at 200°C vs. 15 mins at 180°C); blindly following generic settings ignores the chemistry’s needs. The solution? Demand your supplier’s technical datasheet, then verify your oven’s performance with thermal profiling – mapping actual part temperature, not just ambient air – to ensure every molecule achieves optimal cross-linking.

Secret #4: Storage & Handling – Protecting Your Investment Before Application

Even premium powder turns to costly waste if stored like baking flour – **your powder’s performance is compromised before it ever touches the gun** by invisible threats: moisture, heat, and contamination. Optimal storage demands <50% humidity and temperatures below 25°C (77°F); excess moisture causes clumping that jams feed hoses and creates pinholes as trapped steam erupts during curing, while heat above 30°C (86°F) risks partial curing that degrades flow and adhesion. Always keep powder in sealed original containers – exposure to workshop dust, oils, or mixed residues creates fish eyes and craters, ruining finishes. Crucially, respect shelf life (typically 6-12 months); expired powder loses electrostatic charge efficiency and leveling ability, forcing 20-30% higher application rates. The secret? Treat powder like pharmaceuticals: store sealed in climate-controlled spaces, rotate stock (FIFO), and discard bulging or hardened containers immediately.