Powder Coating Gun Maintenance Tips for Consistent Performance

Your powder coating gun is more than just a tool — it’s the heart of your coating operation. When it’s working well, everything flows smoothly: coatings are even, colors stay consistent, and your production stays on schedule. But like any hardworking equipment, it needs a little care to keep performing its best.

Regular maintenance might seem small, but it makes a big difference. A clean, well-tuned powder coating gun means fewer problems, better finishes, and longer service life. Taking the time to look after it isn’t just about avoiding breakdowns — it’s about protecting the quality and reliability your customers count on.

Daily Maintenance Checklist for Your Powder Coating Gun

Taking just a few minutes at the start and end of each day to care for your powder coating gun can prevent bigger issues down the line. Here’s a simple daily checklist to help keep your gun running smoothly and your finish looking flawless:

- Inspect the nozzle and electrode

Look for signs of wear, damage, or powder buildup. A clogged or worn nozzle can lead to uneven spray and wasted powder.

- Wipe down the gun body

Use a clean, dry cloth to remove any excess powder or dust. Keeping the exterior clean helps prevent contamination and buildup in hard-to-reach areas.

- Check the powder path and hose

Make sure there are no blockages or kinks that could restrict powder flow. Gently tap or blow out any loose powder from the hose.

- Test spray pattern before production

Do a quick spray test to confirm the pattern is even and consistent. This is your early warning sign if something’s off inside the gun.

- Confirm proper grounding

A secure ground is essential for good powder adhesion. Check that your grounding cable is clean, tight, and properly connected.

These small steps don’t take much time, but they go a long way toward keeping your powder coating gun in top shape — and your production line trouble-free.

Weekly Deep Cleaning of the Powder Coating Gun

While daily maintenance keeps things running, a deeper clean once a week helps your powder coating gun stay reliable for the long haul. Over time, fine powder particles can settle inside the gun body, nozzle, and internal components — even if everything looks fine on the surface. Taking the gun apart for a thorough clean removes hidden buildup that could affect spray quality.

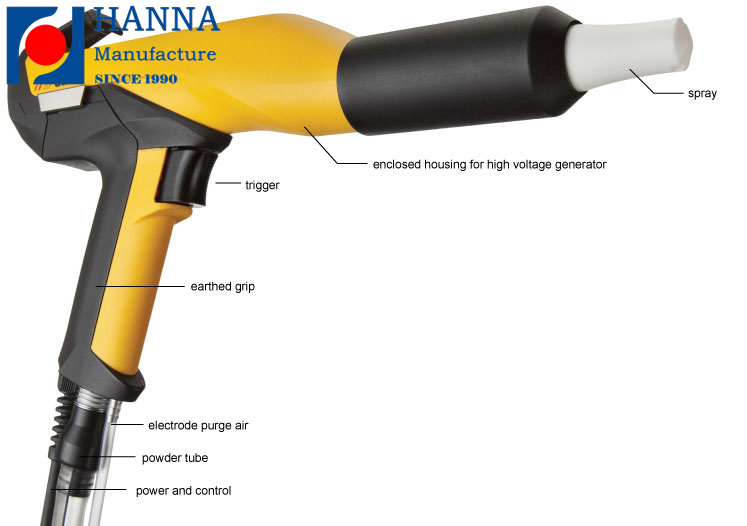

Start by carefully disassembling the gun according to the manufacturer’s instructions. Use clean, dry air to blow out any internal passages, and gently wipe down each part with a lint-free cloth. Pay special attention to the nozzle, diffuser, and electrode — these parts are key to a consistent finish. If anything looks worn or damaged, it might be time to replace it before problems start. With just a little extra effort once a week, your powder coating gun can continue to deliver the smooth, even coverage your work depends on.

Common Powder Coating Gun Issues and How to Prevent Them

- Even a well-maintained powder coating gun can run into trouble now and then. Here are three of the most common issues you might face — and how to prevent them from affecting your work:

- Uneven spray or poor coverage often comes from powder buildup inside the nozzle or worn-out diffuser components. If you notice the spray pattern becoming inconsistent or patchy, try cleaning the nozzle thoroughly. If the problem persists, it may be time to replace the nozzle or other internal parts that control powder flow.

- Weak or interrupted powder flow can result from clogged hoses, moisture in the powder, or blockages in the gun’s internal powder path. To prevent this, make sure all hoses are clear and undamaged, and that your powder is stored in a dry, controlled environment. A simple check of the powder flow before each shift can catch these problems early.

- Poor powder adhesion is usually caused by grounding issues or a worn electrode. If the powder isn’t sticking evenly to your parts, inspect the grounding cable and contact points. A weak or dirty electrode can also reduce charging efficiency — cleaning or replacing it regularly helps ensure strong, consistent attraction between powder and part.

By staying alert to these warning signs and responding with timely maintenance, you’ll keep your powder coating gun working reliably — and your coating results right where they should be.

Storage and Handling Tips to Protect Your Powder Coating Gun

After each use, your powder coating gun should be stored in a clean, dry place to prevent moisture damage and powder buildup. Avoid sharp bends or tight coils in hoses, and handle the gun carefully to protect internal components from unnecessary strain. Cover connectors and fittings when not in use to keep dust and debris out. Even simple habits like gentle storage and avoiding humid environments can go a long way in preserving your gun’s performance and extending its service life.