The Importance of Powder Fluidization in Powder Coating System

Imagine a perfectly coated product moving down the production line, its surface smooth, even, and flawless — almost like a work of art. Behind this perfection lies a crucial process: powder fluidization. In a powder coating system, fluidization isn’t just a supporting act; it’s at the heart of ensuring coating quality and improving operational efficiency. It affects powder distribution, coating adhesion, and even the overall cost-effectiveness of your system.

While many may think of fluidization as simply air helping the powder flow, its true value goes far beyond that. In this article, we’ll explore why powder fluidization is so critical in powder coating systems and how it helps you achieve more efficient and precise coating results.

What is Powder Fluidization in Powder Coating System?

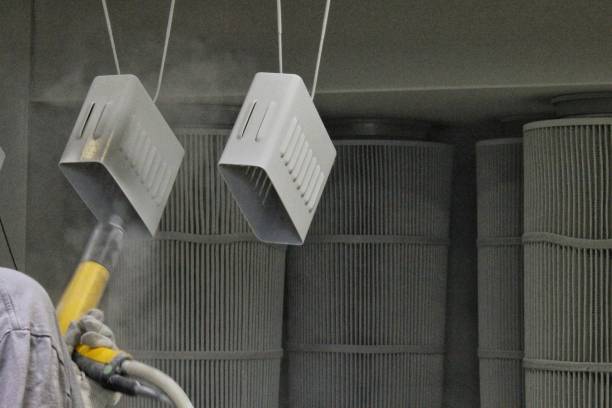

Powder fluidization is a fundamental process that plays a vital role in the performance of a powder coating system. At its core, it involves the introduction of air or vibration to a bed of powder to make it flow more easily, much like a fluid. This is achieved by creating a uniform flow of powder particles, preventing them from clumping together and ensuring a smooth, consistent application.

In simple terms, fluidization helps create an ideal “powder cloud” in which the powder particles are evenly suspended and can be evenly distributed onto the workpieces. Without this process, the powder may not flow smoothly, leading to inconsistent coatings, wasted materials, or even clogging of the spray guns.

The process of fluidization relies on the use of either air or mechanical vibration to agitate the powder, causing it to become less dense and more easily moved. The result is a steady, controlled flow of powder that enhances both the coating’s uniformity and the efficiency of the entire coating system.

This process is especially important in larger-scale operations where consistency and precision are key. By achieving optimal fluidization, powder coating systems can deliver high-quality finishes, reduce defects, and ultimately save time and resources during production.

The Impact of Powder Fluidization on Coating Quality and Efficiency

Powder fluidization doesn’t just make the powder flow better — it directly influences the overall quality of the coating and the efficiency of the entire powder coating system. Here’s a closer look at how fluidization impacts these crucial areas:

Improved Coating Consistency

One of the most noticeable effects of effective fluidization is the uniformity of the coating. When powder is fluidized properly, it flows more consistently, allowing for a smooth, even application on the workpieces. This means no more thick spots, thin areas, or patches that could lead to imperfections in the finish. In powder coating, consistency is key, and fluidization helps ensure that each piece receives the same level of coating across its surface.

Inconsistent coatings can not only affect the appearance but also the durability of the finish. Areas with uneven powder coverage may lead to premature wear, chipping, or peeling, which compromises the product’s longevity. Fluidization helps avoid these issues by maintaining a uniform powder flow, ensuring a high-quality finish every time.

Enhanced Transfer Efficiency

Another major benefit of powder fluidization is the improvement in transfer efficiency. Transfer efficiency refers to how well the powder is applied to the workpiece compared to how much is wasted or lost to the environment. When the powder is properly fluidized, it flows more easily and is more effectively attracted to the workpiece’s surface, reducing overspray and minimizing powder waste.

Higher transfer efficiency not only helps reduce material costs but also improves the environmental sustainability of the operation. It ensures that more powder is actually applied to the workpieces, and less is lost into the air or collected as excess powder that will need to be reprocessed.

Powder Recovery and Cost Savings

Fluidization doesn’t just improve application — it also supports the recovery of unused powder. As powder flows more easily and evenly, the recovery systems in place can more effectively capture oversprayed powder. This recovered powder can often be reused, reducing material waste and cutting costs in the long run.

In a well-optimized powder coating system, the ability to recover and reuse powder can be a significant cost-saving advantage. Proper fluidization aids in maximizing recovery rates by ensuring the powder stays in motion and is more easily collected, rather than clumping or sticking to surfaces in ways that make recovery difficult.

Conclusion

Powder fluidization may seem like a behind-the-scenes process, but its impact on a powder coating system is undeniable. It ensures powder flows evenly, coatings are consistent, and materials are used efficiently. By paying attention to fluidization, manufacturers not only achieve higher-quality finishes but also improve overall productivity and reduce waste. In essence, mastering powder fluidization is key to unlocking the full potential of any powder coating system — turning a routine coating process into a precise, efficient, and reliable operation.