Why Industries Prefer Powder: The Role of the Powder Coating Gun

Walk into any modern factory today and you’ll notice something different: parts and products shining with smooth, flawless finishes that seem built to last. This transformation didn’t happen by chance—it’s the result of industries turning to powder coating as their trusted solution.

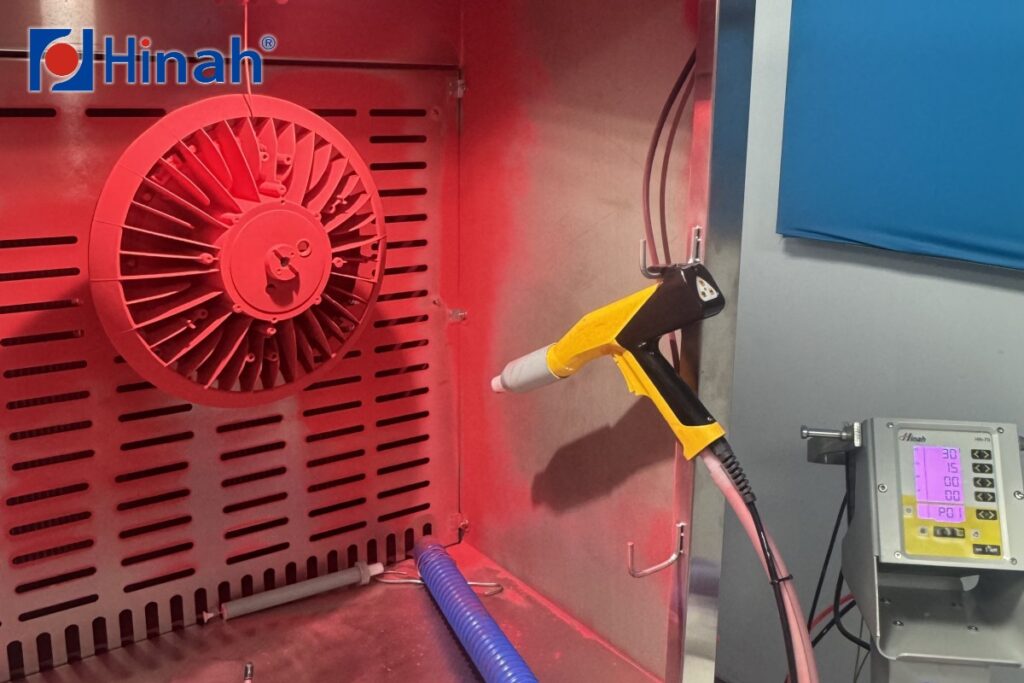

At the very center of this shift stands the powder coating gun. It’s more than just a tool; it’s the reason why powder can flow like silk onto metal, wrapping each surface with even coverage and lasting strength. For manufacturers, the powder coating gun isn’t just about applying paint—it’s about creating products that look better, perform better, and stay reliable in the hands of customers.

How Powder Coating Gun Works

The beauty of powder coating lies in its simplicity—and its science. When a powder coating gun is in action, it takes fine, dry particles of powder and gives them an electric charge. As these charged particles leave the gun, they are naturally attracted to the grounded metal surface, clinging tightly like tiny magnets finding their match.

This process creates a soft, even layer of powder across every curve, edge, and corner. Unlike liquid paint that can drip or run, the powder coating guns make sure every surface is covered with precision. Once the coated part goes into the curing oven, that delicate layer melts and fuses into a tough, protective skin. The result? A finish that doesn’t just look perfect—it’s built to withstand the test of time.

Advantages of Using a Powder Coating Gun in Manufacturing

For manufacturers, every product that leaves the factory floor carries their reputation. This is why the powder coating guns have become such an invaluable ally—they help deliver finishes that don’t just look good on day one, but keep their strength for years.

One of its greatest advantages is consistency. With a powder coating gun, every surface is evenly coated, from smooth panels to tricky corners. That means fewer imperfections, fewer rejects, and less wasted material. Efficiency is another win—because the powder can be collected and reused, very little goes to waste.

And then there’s the environmental impact. Unlike traditional paints that release harmful solvents, the powder coating gun works cleanly, helping industries reduce emissions while still achieving beautiful results. In a world where sustainability matters more than ever, this balance of performance and responsibility is exactly why industries continue to choose powder.

Conclusion

In the end, the reason industries prefer powder is simple—it delivers strength, beauty, and responsibility all in one finish. And none of it would be possible without the coating guns.

This tool is more than a sprayer; it’s the bridge between raw metal and a surface that customers can trust for years. With every smooth coat, it helps manufacturers reduce waste, cut costs, and protect the environment—while giving products the flawless look that modern markets demand.

For today’s industries, choosing powder isn’t just a technical decision—it’s a statement of quality and sustainability. And standing at the heart of that choice is the powder coating gun, making powder not just the better option, but the preferred one.