Products and Application:

Hinah powder coatings products are widely used in various fields of surface treatment: traffic facilities, aluminum profiles, metal cabinets, hardware tools, household electrical appliances, storage facilities, sports products, metal casting parts, automotive and agricultural machinery, logistics equipment, petroleum and natural gas pipelines.

Advantage:

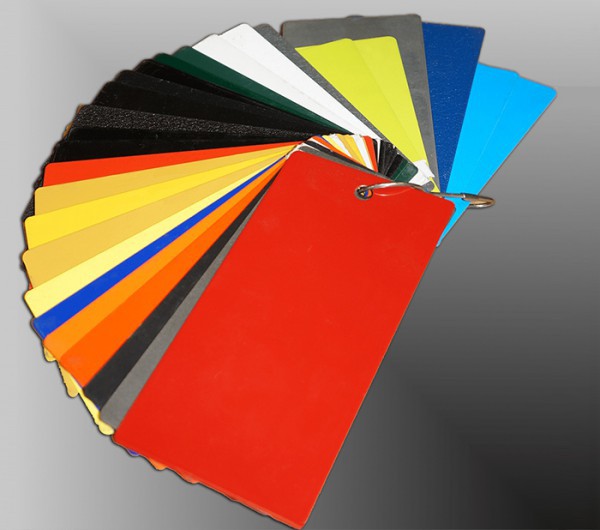

Good adhesion, good mechanical property, strong coating film,

beautiful film, customized glossiness.

The main difference between our powder coatings and other paints is that the powders do not require solvents in any phase of the application. Therefore, our powder coatings are more eco-friendly than other paints which contain solvents that guarantee the flow and evaporate after application.

1. Uniform, durable coating surface without sagging or running

2. Close to zero VOC content = environmentally friendly

3. Fast application and short curing time

Test process:

Hinah Powder Coating has been adhering to the people-oriented concept of green environmental protection. All our products have passed the heavy metal test in compliance with customers need.

Construction requirements:

If your are currently using powder from someone else , or you are currently using our powder but different color specie, you must have your painting system completely clean before the job, that will keep you away from powder messing up and kind of failed coating or color defects by pollution issue.

1. Keep your device and work environment clean to go, that will prevent large particle to show up on coating by avoiding dust going in.

2. Recycled powder would pass through filter mesh 140 before the job

3. Workpiece must perfectly pass through pretreatment stage to make sure no residue left but that phosphate film ready to go, no grease, no rust,nothing left to fail adhesion force.

4. Electrostatic gun will have shoot voltage shift from 50kv to 90kv,Gives excellent atomization work, and spray powder equally like a even work.

5. Target Temperature 200±5℃(workpiece temperature) 10 minutes will do curing job, do over limit would make your coating poor as far as you do.

6. Make sure your ventilation and static ground work well, so pollution will be limited in control and worker will be secured.